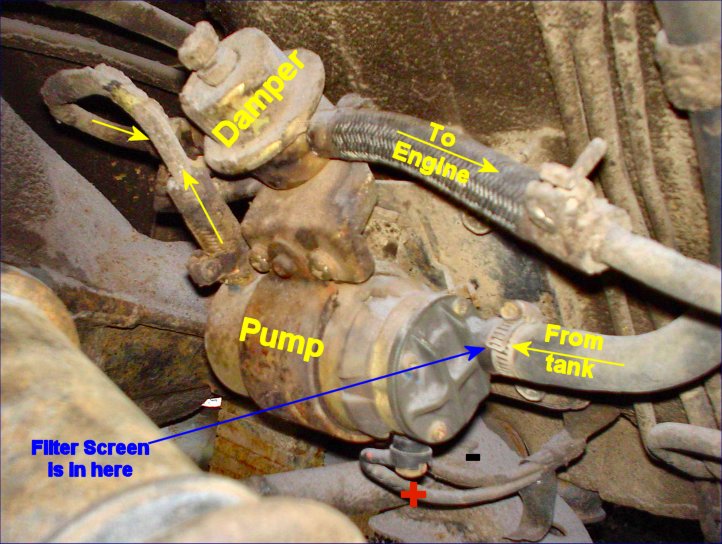

Location

Quieting a noisy fuel pump (only two steps)

My fuel pump gradually started to get louder until it was annoying. It was especially loud when idling.

I assumed it was the fuel damper breaking so I changed the fuel damper. This lasted for a day then the noise returned. I assumed both dampers were bad.

Yesterday, I decided to investigate further. I noted that the rubber shock mounts seemed to be ok.. but what the heck, I will add some more isolation.

I simply cut two pieces of the foam craft paper that you can buy at most "dollar stores" in 8.5" X 11" sheets. These pieces fit between body of the pump and the circular body clamps.

I also cut two pieces of rubber fuel hose ~ 7mm thick. These "washers" fit between the top body clamp and the main pump holder. The two Philips screws pass through the "washers"

The result is a pump that is very quiet. I can not hear it when idling.

Fuel Routing

Note the positive terminal is furthest from the body. There is a connector behind the passenger's seat where the back wall meets the floor (flip the carpet). This is a convenient place for disconnecting the pump. Simply pull the disconnected cables and rubber grommet from the pump side.

Fuel Filter Screen

The filter screen at the input to the pump often gets clogged with debris from the tank (rust, gunk, varnish)... especially with cars that have sat for a while. Removing and cleaning the screen is a simple task. Just remember to clamp the fuel hose between the tank and pump before disconnecting the line.

Fuel Pump Checks

Author: 79-280-ZX (---.sympatico.ca)

Date: Sep 27, 6:48am

Pumping from one can to another with no restriction (i.e. no FPR) should result

in zero PSI on the outlet line but the pump should push at least one litre in 30

seconds.

If you hook up can 1->pump->FP gauge->FPR->can 2 then you should see

37 PSI pressure and still get ~ 1 litre in 30 seconds out of the return port of

the FPR.

If you do not get 1 litre in 30 seconds the pump is probably toast.

If you use a 2 litre coke bottle and you see air bubbles coming out of the

return hose with this set up the pump is sucking air.

If you do not see air bubbles with the can to can method but you do when hooked

up to the fuel tank then suspect a hole / leak in the tank pickup tube or the

pickup tube is above the level of fuel in the tank.

Wayne Monteath

Masham, Quebec.

1979 280ZX 2+2

1981 280ZX 2+2

Fuel Pump Control Circuit Information

Author: 79-280-ZX (---.sympatico.ca)

Date: Jul 1, 9:34am

Well we have some confusion here. This question comes up at least once a week

and gets as many wrong answers as correct ones. So, here in one basket, is the

correct answers for all years from 75 to 83.

The fuel pump control for the 75 - 77 N/A.

When the engine is not running the flap in the AFM is closed and the fuel pump

control switch in the AFM is OPEN. When the key is turned from "OFF"

to "RUN" there is no continuity through the fuel pump switch in the

AFM and the fuel pump should not run. When the key is turned to

"START" the engine turns over AND the fuel pump relay closes which

starts the fuel pump. As air is sucked past the flap in the AFM it opens and the

FUEL PUMP contacts in the AFM close. When the engine starts the air flow through

the AFM keeps the fuel pump running because the switch is closed. If the engine

stops / stalls the flap in the AFM closes and the fuel pump control switch in

the AFM opens thereby shutting off the fuel pump.

The fuel pump control for the 78 - 81 N/A.

When the engine is not running the oil pressure switch is closed and the

transistor at the 'L' terminal of the alternator is "closed" and BOTH

idiot lights for ALT and OIL are ON. When the key is turned to ON the idiot

lights are on and the fuel pump is OFF. The fuel pump only "starts"

when the key is turned to Start. These years used three relays to control the

fuel pump. If the engine stops / stalls the loss of BOTH ALT and OIL signals

simultaneously shuts off the fuel pump.

The fuel pump control for the 82 - 83 N/A.

For 82 - 83 N/A models the fuel pump starts and runs for ~ 5 seconds when the

key is turned from "off" to "on" and then shuts the fuel

pump "off" until the key is further turned to "start" at

which time the fuel pump starts up again.

The ECU uses pin 13 to control the fuel pump operation since it does not have a

FPCM. When the ignition switch is turned from "off" to "on"

the main EFI relay closes and supplies battery voltage to pin 27 of the ECU. The

ECU then supplies battery voltage to pin 13 of the ECU to close the Fuel Pump

Relay for ~ 5 seconds. When the ignition switch is further advanced to the

"start" position the "start" signal is sent to pin 26 of the

ECU which in turn allows the ECU to provide battery voltage to pin 13 thus

starting the fuel pump again.

The ECU also monitors the Ignition Coil Trigger on pin 18 coming from the '-'

ignition coil terminal. If the engine stops / stalls or the engine speed drops

below 50 RPM the ECU removes battery voltage from pin 13 which causes the Fuel

Pump relay to open and stop the fuel pump.

The fuel pump control for the 81 - 83 Turbo models.

For all 81 - 83 Turbo models the fuel pump starts and runs for ~ 5 seconds when

the key is turned from "off" to "on" and then shuts the fuel

pump "off" until the key is further turned to "start" at

which time the fuel pump starts up again. The 81 Turbo ECCS used pin 16 to

control the fuel pump operation since it did not have a FPCM. All 82 - 83 Turbo

models used a Fuel Pump Control Modulator in conjunction with the ECCS to

control the fuel pump operation. If the engine stops / stalls the loss of the

ignition signal stops the fuel pump under control of the ECCS and / or the FPCM.

Wayne Monteath

Masham, Quebec.

1979 280ZX 2+2

1981 280ZX 2+2

Post Edited (Sep 18, 1:17am)

More excellent info from Wayne Monteath

Fuel Pump Upgrades

Two "o-rings" under this top plate seal the impellor. If the seals open, the pump sucks air and can not build enough pressure and/or flow. (Sometimes, engine surges at high RPM under load is a sign of air leaks and related low fuel pressure/delivery) Replacing the o-rings may be needed but be sure to use "exactly" the same size. I tried new ones which were ~ 1mm thicker and the pump would not work properly. Also use o-rings that are not soluble in gasoline. Usually, tightening the top plate cures the problem.

An obvious upgrade is to replace the Philips screws with bolts so that the top plate can be torqued tighter (the Philips screws have soft heads... maybe brass to reduce electrolysis?). Washers and lock washers also help. I used four M? X 14mm length.

The outlet port at the top of the pump is another area where others have had problems. It has a built in check valve that can clog or break. You can remove the outlet port assembly with a 14mm wrench. Inspect the valve and blow on it. It is a one way. Use "yellow" Teflon tape (the gas type) to seal the threads when reassembling.

Fuel Pump Internals