The above is an exaggerated cross-section of a cam

lobe.

The difference between long and short axis is the "cam lift" or

"lobe lift".

Lobe lift is the distance, the cam pushes the rocker down at the point of

contact.

For a stock Z Cam, the short axis is ~ 33.3mm and the long axis is ~

40.3mm.

This gives a lobe lift of 7mm (0.276")

The above is an also exaggerated cross-section of

a ground cam lobe that is a so called "hot cam".

It should be easy to see that the lift is greater than stock and the geometry

is more severe.

For a typical Hot Z Cam, the short axis is ~ 30mm and the long axis is ~ 40mm

(these values will vary depending on grind shape).

This gives a lobe lift of 10mm. (0.394")

The above shows how a stock cam is ground to make

a hot cam.

The base circle diameter (short axis) is reduced while the long axis

remains close to stock.

The decreased base circle must be compensated in the valve train.

The lash pad is what compensates for the decreased base circle.

Above, you can see the stock cam on the left and the hot cam on the right.

Since the valve can not be lengthened (without replacing) and it can not be raised (without tons of hassle), the valve tip remains the same distance from the top of the head.

Likewise, the center of the cam is always a fixed distance from the top of the head (unless you shim the cam towers).

The decreased lobe's base circle effectively causes the rocker arm to be raised in order to correctly contact the cam (both ends of cam are raised in parallel).

The lash pad is what compensates for the decreased base circle and raises the cam end of the rocker. (The other end of the rocker is raised by the threaded adjusting pivot).

Note: springs, clips, retainer, lock nuts, shims and such has been eliminated from the above drawing for clarity.

The stock lash pad is 3mm (0.118") high. If the hot cam has 3mm removed from the back side of the lobe, the lash pad will require ~ 3mm extra height so it will be ~6mm or 0.236'.

Aftermarket lash pads were made from 0.150" to 0.330" in 0.01" increments. Not sure what is available now.

Another item to review is lift. In the above diagram, it is easy to see that the rocker pivots at the round adjuster/pivot. The geometry should clearly show it travels further at the valve stem than where the cam lobe contacts it.

The lift at the cam is called lobe lift. The lift at the valve is called valve lift.

Stock Lobe lift on a 77 N47 head is 7mm (0.276")

Stock Valve lift on a 77 N47 head is 10.5mm (0.413")

The translation factor between the two is ~1.5

For the above hot cam with 10mm of lobe lift, the valve lift would be 15mm (0.590")

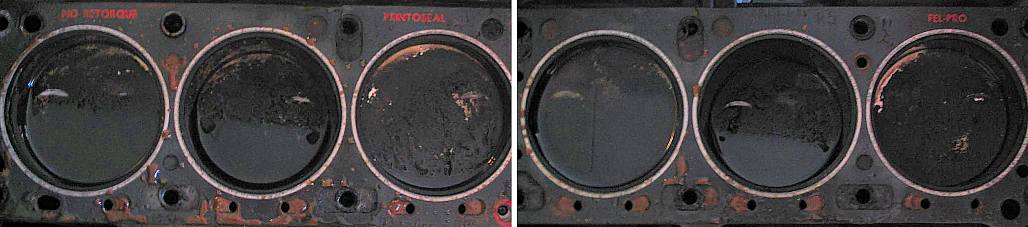

This picture shows the space between the cam lobe and rocker arm.

It is called the valve lash.

In layman's terms, it means that when the valve is pulled up into the valve seat by the springs (valve is closed), all of the springs force is solely applied to the valve seat and the cam is not holding the valve off the seat.

The valve lash ensures the valve is not held off the seat when it is supposed to be closed and sealing AND it ensures the rocker does not fly upward too far after the closing valve tip pushes it up.

To little valve lash means the valve is not closing fully.

To much valve lash means the valve will travel further into the seat and the rocket arm will fly up further before colliding with the cam (the lash pad will also chatter). All of this excess travel will result in a noisy valve train and the famous tapping!

For a hot engine, the lash is 0.30mm for exhaust and 0.25mm for intake.

For a cold engine, the lash is 0.25mm for exhaust and 0.20mm for intake.

Incorrect valve lash will usually result in a tapping sound from the valve cover area.

And if you get it wrong. The valves "float" at high rpms and get beat by the pistons.

Note, only the smaller exhaust valves hit.