Air : Fuel Ratio Overview

Air and fuel are ideally mixed at a mass ratio of 14.7:1 (14.7 parts air to 1 part gasoline where parts are in kgs or lbs).

This ratio is called the "stoichiometric" ratio which roughly translates to chemically ideal ratio in which a burn of both air and fuel components are completely consumed.

It is similar to the ratio for water H2O in which two parts Hydrogen combine with one part Oxygen.

If the gasoline to air ratio is not managed within the engine, side effects and problems can occur. Some side effects are good (cooler combustion temp, better mpg, more power), others are bad (melted pistons, poor mpg, bad emissions). Thus it is desirable for the engine to run slightly excess gasoline (rich) at times and slightly less gasoline (lean) at other times but for the most part, keeping the ration near 14.7 to 1 is the ideal

Running Lean

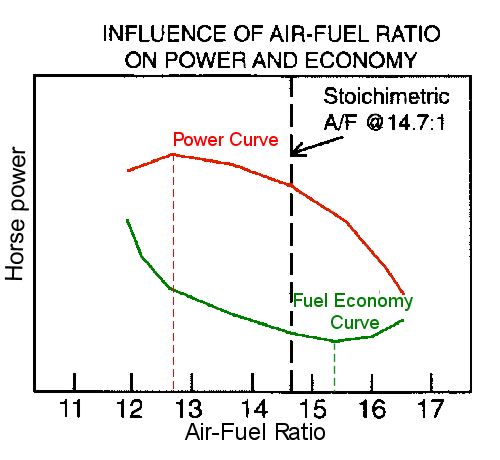

For an automobile, having a ratio where there is "extra air" (say 20:1) results in the mixture being "lean" or "thinned of gas". The good aspect of running lean is that there is ample air to mix with the gasoline to ensure nearly all of it gets burned however, there is still extra air kicking around that contributes to heat. This results in gasoline savings (better mpg) but the side effect is a very hot combustion chamber which can melt valves and pistons. Hot combustion chambers can also pre-ignite the air-fuel charge before the spark plug fires. This is called detonation and is more common with high compression engines and turbocharged engines. Another side effect is slightly less power when accelerating.

Running slightly lean and maintaining acceptable combustion temperatures is great for cruising at a constant speed down a highway to conserve fuel. In fact cars are designed to do this. The rule of thumb ratio for this is 15.5:1

Running Rich

Having a ratio where there is "extra fuel" (say 7.35:1 aka 14.7:2) results in the mixture being "rich" or "laden with gas". This results in greater gas consumption but the side effect is a cooler combustion chamber, and inefficient burn as there is not enough air to burn all of the fuel. The result is a sooty combustion and poor gas mileage. In fact if there is too much fuel, the chamber and plugs can be covered in soot in just a couple of minutes and the spark plugs become so fouled that the plugs will not fire and the car won't start. Another by-product of running rich is that the un-burnt gasoline can ignite in the hot manifold/exhaust and cause them to glow orange. Emissions are also increased and a black smoke can usually be seen coming out the exhaust and it may smell like nail polish.

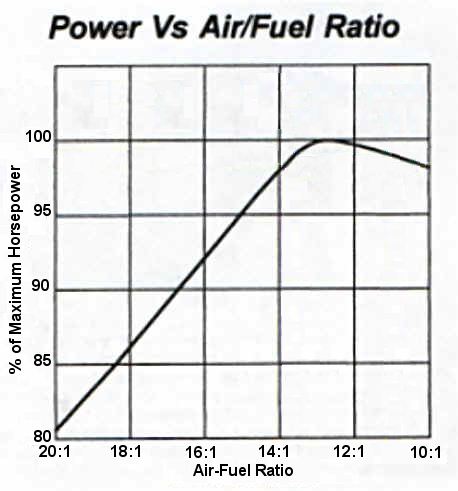

Running slightly rich is great for accelerating and at high rpms as it ensures that nearly all of the air briefly sucked into the combustion chamber is used. (If you analyze engines, you realize the limiting factor to power is how much air the engine can pull into the chamber with each intake cycle. If you can burn all of this air, you can get maximum power). For turbo cars and high compression cars, the extra gas also has a nice side effect of cooling the mixture and preventing heat triggered igniting of the air&fuel (aka detonation) before the spark ignites it. The rule of thumb for richness and maximum power is 12:5 to 1 at maximum HP point.

Problems causing a Lean mixture

Fuel delivery problems

- Clogged injectors

- Incorrect injectors

- Low fuel pressure

- Clogged fuel supply line

- Clogged fuel filters

- Weak fuel pump

- Faulty fuel pressure regulator

Air/Fuel management faults

- Faulty coolant temperature sensors

- Faulty air temperature sensor

- Faulty air flow meter (AFM)

- Faulty mass air flow meter (MAF)

- Faulty manifold air pressure sensor (MAP)

- Faulty engine computer/control unit (ECU)

- Faulty wire (corroded connection, broken or disconnected) to any of the above

Air/Fuel sensor configuration

- Incorrectly set AFM

- Incorrectly set Throttle Position switch (TPS)

- Air Leaks that bypass air metering device (AFM/MAF)

- Ripped downstream rubber boot in manifold

- Disconnected hose to manifold

- Poor engine seal or gasket

- Incorrectly connected hose to manifold

Problems causing a Rich mixture

Fuel delivery problems

- Incorrect injectors

- High fuel pressure

- Clogged fuel return line

- Faulty fuel pressure regulator

- Stuck-Open or leaky injectors

Air/Fuel management faults

- Faulty coolant temperature sensors

- Faulty air temperature sensor

- Faulty air flow meter (AFM)

- Faulty mass air flow meter (MAF)

- Faulty manifold air pressure sensor (MAP)

- Faulty engine computer/control unit (ECU)

- Faulty wire (corroded connection, broken or disconnected) to any of the above

Air/Fuel sensor configuration

- Incorrectly set AFM

- Incorrectly set Throttle Position switch (TPS)

Common diagnostics to determine if you have an air/fuel problem.

Read Plugs

- Running rich will leave dark dry sooty deposits on plugs. When plugs are this bad, fuel is too rich and car will not start. If you do get it started, it will not run long.

- Running lean will have a very white insulator with blistered metal deposits on plugs. Metal electrodes may even be blue from the heat.

- Here is an ideal burn

Compare power to a similar Z

- If you have your car in good form but lack the grunt power, air fuel mixture can be the problem.

This is a Dyno plot of HP and Torque ( top two lines) and Air to Fuel ratio (bottom line). Note it is around 12.5 at maximum torque.

Check fuel consumption

- Most 280z's get 21 to 25mpg on highway depending on state of car and air/fuel setting.

Common items to check

- The weakest point on a 280Z are the EFI electrical connections in the engine compartment. These typically corrode at the connector and cause either high resistance or open circuits. Both of these conditions can fool the ECU into sending too much or too little fuel. (click here for contact cleaning tech tip)

- Water (Coolant) Temperature sensor. Even though, this is associated with the above list item, I am making it a separate list item because it is the most common problem on a 280z found to be running rich. Corroded connector, disconnected connector, connector mixed up and swapped with Thermotime neighbour or corroded bullet connectors where the pigtail ends (~1 foot downstream from this connector) are the item to verify.

Here is the coiled-up water temp sensor "pigtail" with Bosch clip connector on left and two bullet connectors on right

Bullet connectors and where they tie into the EFI harness. This is a common corrosion point (near TB and fuel rail)

- Fuel pressure. Measured at return from fuel rail. It should be ~ 34psi above manifold pressure when rev-ing or idling.

If it is low, check for:

- clogged fuel filter

- clogged inlet screen to fuel pump

- clogged tank pick-up

- clogged fuel line

- weak fuel pump

- air leak in hose between tank and pump

- faulty fuel pressure regulator

If it is high, check for:

- Restriction in return line to tank

- Faulty fuel pump

- Faulty fuel pressure regulator

- AFM functioning (click here)

- TPS adjustment (click here)

- EFI system checks (click here)

- Manifold/Engine Vacuum Leaks (click here)

Tools

Air Fuel Meter

An air fuel meter can measure air fuel ratio. There are two types of sensors: narrow band and wide band. The wideband is most stable and works the best but it is significantly more expensive. A narrow band kit can be purchased for ~ $100. A junkyard is a great source of sensors (aka O2 sensor).

Exhaust Gas Temperature Gauge (aka Pyrometer)

An EGT meter can measure temperature of exhaust gas. The temperature increases as the mixture leans. This can cause thermal stress, detonation or even component melting.

This information is most useful during wide open throttle (WOT) engine operation. At WOT, values between 850ºC (1562ºF) and 900ºC (1652ºF) are often considered ideal; temperatures below 800ºC (1472ºF) are considered too rich; temperatures above 925ºC (1697ºF) and approaching 1000ºC (1832ºF) are considered dangerously lean and can result in excessive engine detonation (knock) and possibly burnt or melted components (valves, spark plugs, pistons, rings). The placement of the EGT probe affects the measurement (the farther the probe is from the head exhaust port the cooler the temperature can be) as does the amount of ignition timing advance (more advance can mean cooler temperatures). Be aware that some EGT gauges only read to 871ºC (1600ºF)