Bottom Line:

Get for

your Zcar!

for

your Zcar!

Anne G. Kaye recommends them!

Comparisons:

Old vs. New

Above, on the left, is the tried and true NGK BR6ES-11

copper plug that has been around for years. On the right is the projected plug.

Look at the plug history below and try to figure out why Nissan started with

projected tips then switched to non-projected for N42 and most N47 heads then

switched back to projects midway through the N47 line. My guess is pollution or

compression related?

The part number of projected plugs started with BPR...

where the P signifies a projected plug. The 6 and 5 numbers are the arbitrary

NGK temperature at which the projection stays when operating. Lower numbers are

hotter so the projection on a 5 plug is hotter than on a 6 plug. This heat helps

to burn off carbon, fuel additive and oil deposits from the plug and this

cleanliness makes it operate better. Plug temperature does not affect how hot

the combustion chamber is (air/fuel mix does). The only caution when

running a hot plug is that it can trigger detonation in a turbo

application or high compression application. However, many people recommend NGK

5 heat range plugs and report no problems when using them.

btw the R in the product code means a resistor is

integrated to reduce RF noise interference. My plugs measure ~ 4.5kohms of

resistance.

Old vs. Newest (latest and greatest)

On the right is the newer "V-Groove" NGK ZFR6F-11 copper plug whose

tip projects further into the cylinder than a BPR and promotes a better burn: "[The

ZFR6F-11] is a 'V-Power' plug with a projected tip which extends out into the

center of the chamber. Projected tips provide a more complete burn through the

rev range, creating "free horsepower" and improving throttle response.

They also simulate advancing the timing slightly by firing the mixture

faster."

normal center conductor vs. v-groove center conductor

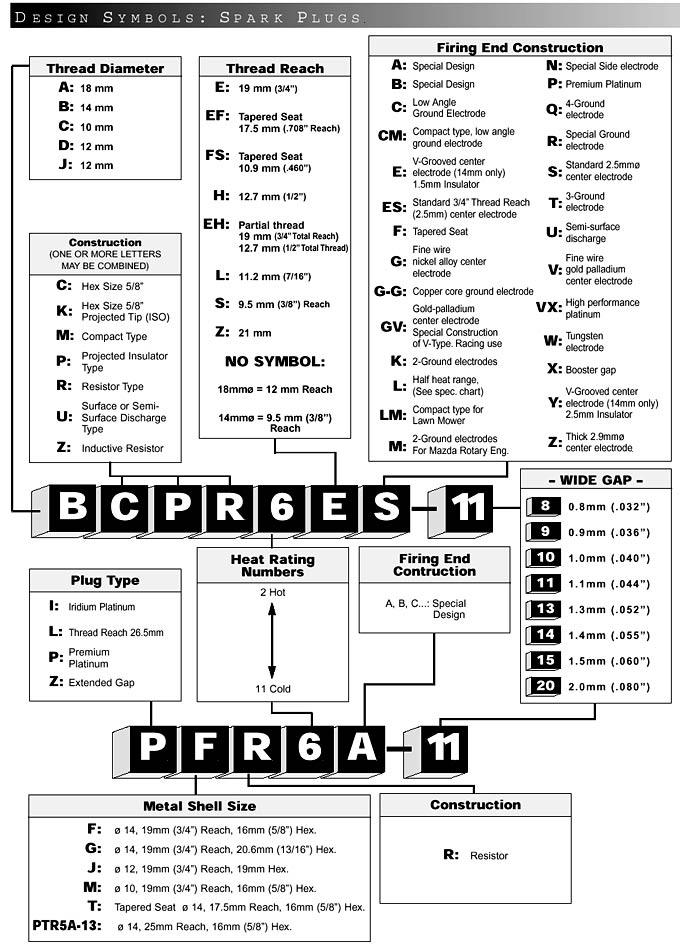

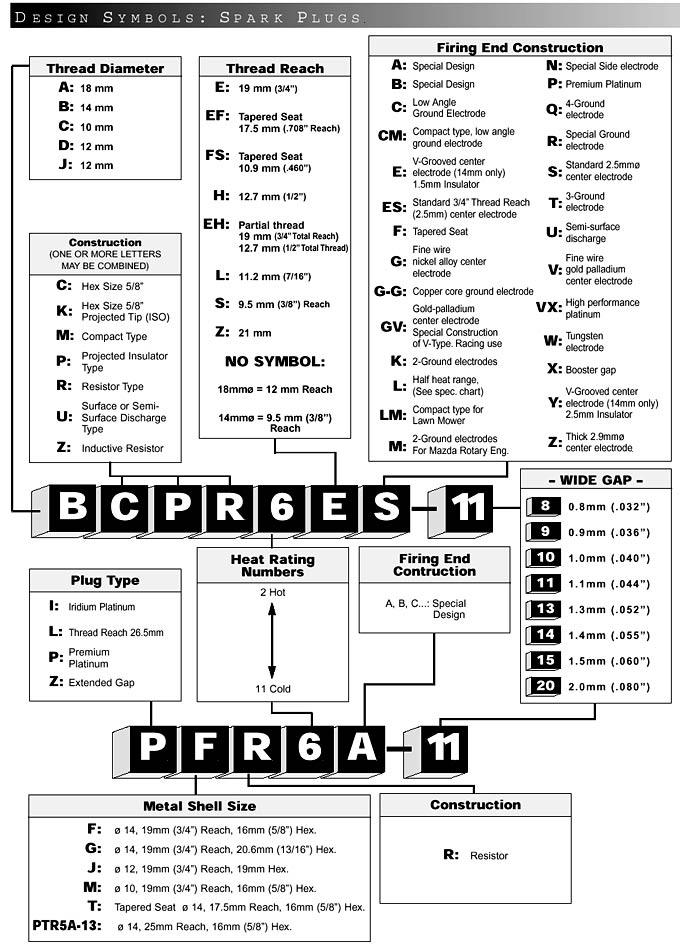

NGK Product Code Chart:

NGK Iridium IX Plugs

If the old and new are not good enough then get the latest NGK "Top of

Line" Iridium plugs that substitute for the above. The part numbers are

BPR6EIX-11 and ZFR6FIX-11.

The iridium plug has a finer center conductor that is made out of the tougher

metal. They last longer and spark is different due to the finer "pin".

Here is the blurb:

Iridium is a silver-white precious metal that is among the densest materials on

earth. Since it’s so dense, it will outlast Platinum and Copper

plugs. Plus this ultra- hard material also enables the plug center

electrode to be 25% narrower than Platinum, and 75% narrower than conventional

nickel electrodes, which requires less voltage to spark, and delivers increased

burn efficiency, sparks at leaner air/fuel mixtures, and

produces better gas mileage and higher horsepower. Iridium plugs are a

must for turbocharged and high compression or high revving NA motors.

WARNING: Do not

gap Iridium plugs, stress to the tip may cause it to break off during use!!

Historical Z Plugs

-1970-1974 240 and 260Z's came with BP6ES

-1975-76 280Z's came with B6ES

-1977-'79 280Z and 280ZX's came with B6ES-11

-1980 280ZX's came with BP6ES-11

-1981-82 280ZX's came with BPR6ES-11

Z Plug Gap

1.0 to 1.1mm

0.039 to 0.043in

Z Plug Torque

10 to 12ft-lbs

WARNING: Always

try to remove plugs with engine cold.

NGK Plug Wires

Early Zcar's use NGK part NE-61 (not shown but similar)

Most of the parts places in Canada have NGK NE61

sets for around $40.

Part Numbers: Nissan # 22450-P7125 (N/A) # 22450-P9026 (Turbo)

NGK Variable Pitch resistor cables provide uniform resistance and insure

outstanding electrical conductivity in high quality cables. This produces the

impedance necessary to suppress radio interference throughout the entire

frequency spectrum.

The RFI (Radio Frequency Interference) noise is generated by ignition systems

and can interfere with computer controls and on-board electronic systems of late

model vehicles. When used in combination with resistor spark plugs, NGK resistor

cables provide exceptional noise suppression without negatively affecting engine

performance.

A layer of ferrite magnetic material wrapped with variable pitch metal wire

covers the fibreglass strand core. The inner layer of insulation is made of

polyvinyl chloride, with a heat resistance of 100ºC. The outer jacket is made

of one of two materials, depending upon the application. These materials are:

1) EPDM (Ethylene Propylene Dien Monomer) a rubber compound that is heat

resistant to 180ºC

2) NGK's new silicone vinyl insulation that is heat resistant to 250ºC

NGK cable resistance is only a fraction of that found in ordinary solid carbon

core resistor cables. Ordinary solid carbon-core wires, used as original

equipment on most Japanese vehicles, are not as efficient and effective.

In addition, the resistance of solid carbon-core wires tends to increase over a

period of time, while the resistance of NGK's wire-wound cables remain virtually

unchanged. While resistance is necessary to suppress radio frequency

interference (RFI), too much resistance reduces sparking and ignition energy.

NGK resistor cables are packaged in sets consisting of one coil wire (where

applicable), and four, five or six plug wires, as appropriate. Every set is

tailored to the right cable length for the exact make and model specified

Leads - Technical Information

-NGK are a stainless steel variable pitch. The variation in winding

(loose-tight) is good for noise suppression thus preventing noise on

the car radio or interference with the in car computer.

-NGK are a stainless steel variable pitch. The variation in winding

(loose-tight) is good for noise suppression thus preventing noise on

the car radio or interference with the in car computer.

-Some competitors leads are stainless steel as well but are not variable pitch.

-Operating temp range is -50 C to 200 C for the silicone leads, and up to 180 C

for EPDM rubber (Ethylene Propylene Dien Monomer).

-The material used for the outer jacket depends on which is best for the

particular application.

-NGK leads offer a very good conductivity and noise suppression.

-Our leads have 8 k/ohm resistance which increases after about 150 hours.

-Leads have to be replaced as resistance gets too high.

-Leads resistance can be tested with special ohm meter. First dial in the length

of lead & the meter will measure the resistance value per meter.

-NGK lead kits are used in the following OE applications:

-Rolls Royce

-GM, Fiat, VW, and Ford (All in Brazil only).

-Many standard leads consist of a carbon wire conductor covered by insulation

rubber then glass fibre then insulation jacket. There is no advantage to thicker

leads. They use cheaper quality insulation jacket so it needs to be thicker.

-NGK currently manufacture 7 mm thick leads with the exception of some late

models which use 5 mm as O.E.

-NGK leads are suitable for use with high energy ignition systems.

-NGK offer a 2 year warranty on our Lead Kits.

My Purchase

I just obtained mine from clubplug,net $31cdn +

$5 shipping!

Each wire had it's own label.

for your Zcar!

-NGK are a stainless steel variable pitch. The variation in winding

(loose-tight) is good for noise suppression thus preventing noise on

the car radio or interference with the in car computer.

-NGK are a stainless steel variable pitch. The variation in winding

(loose-tight) is good for noise suppression thus preventing noise on

the car radio or interference with the in car computer.