Jack up, remove wheel and caliper.

Remove dust cap (a tool exists for this)

Remove cotter pin

Remove locking nut, nut, washer and outer bearing

Parts removed so far: dust cap, cotter pin, locking nut, nut, bearing, washer

Note: there is no seal on the outer

bearing as the dust cap serves the same function

View after outer bearing is removed.

Pull wheel hub assembly. Here is a pic of the back side. You can see the inner

bearing and its seal

Pic of the spindle with hub removed.

Note: old grease typically has lead in it. dispose properly ( 78

2plus2 )

If you are replacing the rotor then you need to do this to separate the hub

from the rotor.

Pry out the inner bearing seal

Pull out the inner bearing

Carefully drive out races

Note:

Be careful not the gall the hub when

driving out the old races. That can make getting the new ones in a real pain.

If the hubs are already galled, a small sanding drum on a rotary tool can be

used to smooth the surface. (HizAndHerz)

I like to throw the races in the freezer a couple of hours beforehand and warm

up the hub a little bit to make the races go in easier. (HizAndHerz)

Here is the old race. It is easy to see the wear

Home made front wheel outer race driver. 1" pipe coupler with slight grinding

to fit (thread is inside)

Here is home made front wheel inner bearing driver 2" threaded pipe

coupler. Note the lightly ground threads to make it fit.

Apply anti-seize to the hub where the race will be placed

Use tool to drive and seat race. Tap gently and uniformly

Job done. Nice fresh race

Repeat with inner bearing

Inner race is seated

Clean!!!

Clean!

Wheel grease

Ready to go

Clean hands

Grease inner race

Grease inner bearing

Note: do this with bearing in a clear plastic bag with grease to save a mess

( 78

2plus2 )

Inner seal

Grease inner seal then install

Completed inner bearing and seal

Spindle is now ready for hub

Mount brake guard if removed.

Prep spindle with scotch brite and rope

Shiny and new

Clean off the scotch brite remnants

Grease the spindle

Messy but ready

Greased up inner and grease packed hub

Really packed hub

Place hub on spindle (Brembo rotors)

New outer bearing

New outer bearing

Greased outer bearing

Grease outer race

Install outer bearing and grease

Install washer

Install nut and torque (20ft-lbs). Rotate a few

times then re-torque

Test pre-load with fish scale and wheel stud, Adjust nut if needed

~1lb or 2kg

Install nut lock

If the nut lock's V slots do not line up with cotter

pin hole, simply pull nut lock off the nut, rotate the nut lock then reinstall.

The V's are offset so

that they will line up

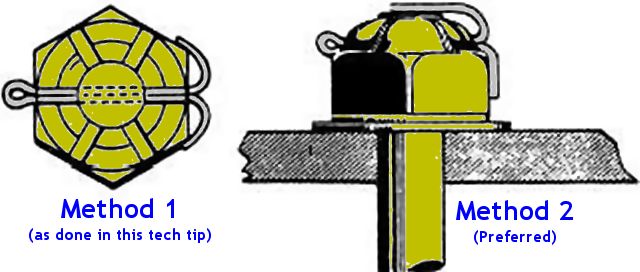

Install NEW cotter pin

Installed

Bend cotter pin

Note:

Cotter pin not installed correctly. The

pin goes with the round bulge facing out. Before using a new pin, hold one end

in a vise and twist it's other end 90 degr. Now you have the famous Rolls Royce

twist that allows a correct install. so that the two legs of the pin can be

folded back against the outside of the retainer back to front w/o hitting the

grease cap or having to cut off one leg of the pin.

( 78

2plus2 )

More grease

Grease cup

Done