Why Swap?

- The original '77 280z's build has an

external mechanical voltage regulator that is unreliable and unstable with

age. It is actually based upon elements that open and close many times

each second due to heating and cooling. The principal is not much

different than the overheat protection devices commonly used in your

toaster and hairdryer. It also requires frequent adjustments of gaps much

like spark plugs.. The newer ZX alternator incorporates a built in

solid-state voltage regulator that requires no maintenance and is more

stable.

- The wiring between the alternator and

voltage regulator typically is problematic. On the ZX unit, the regulator

is inside the alternator body so there are no interconnections to worry

about.

- The Z alternator is rated at 50A. The ZX

alternator is rated at 60A (It is physically bigger)

- The upgrade is pretty much bolt and go. Two

wires need to be jumpered or spliced and that is it!

- The ZX unit is newer, readily available in

junk yards and inexpensive.

- The ZX unit is rock solid an the DC voltage

is 14.45V at all RPMS (as measured on mine).

- No more wavering Voltage gauge or hunting of

the fuel pump.

- This swap worked great in my 77 280z. I

assume it will work in 75 & 76 280Z's. I do not know about 240 or 260

Z's.

Compatible Donor Alternators:

- All 280ZX units. Turbos are 70Amp and N/A

are 60Amp. '78 Z units also work and are 60Aamp.

- Other Nissan units should work but

size or wiring or pulleys may require mods to work (double check your

potential source against pics of the stock unit below)

Big Thanks to Z-Creations for info on how to do

this swap! Click

Here.

Physical Comparison:

ZX alternator on left, Z alternator on right.

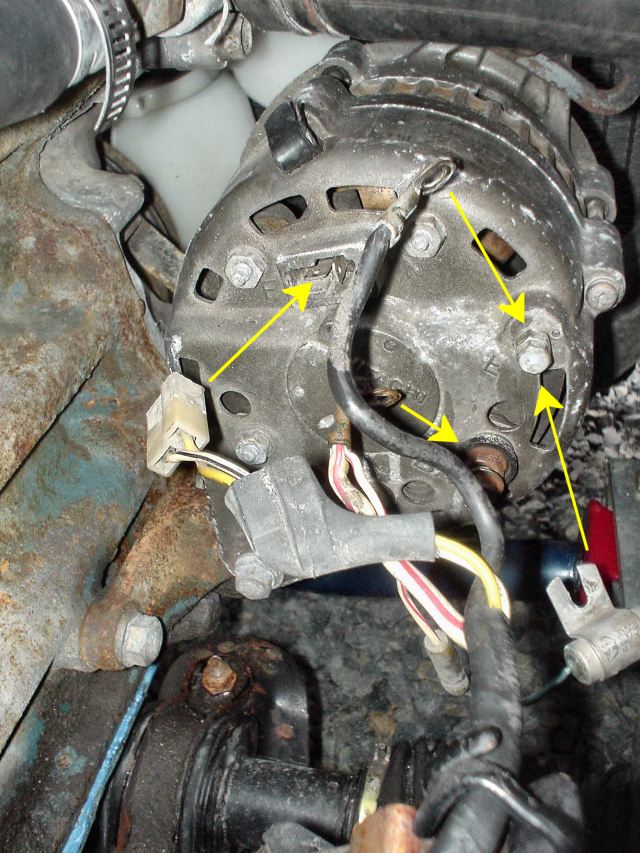

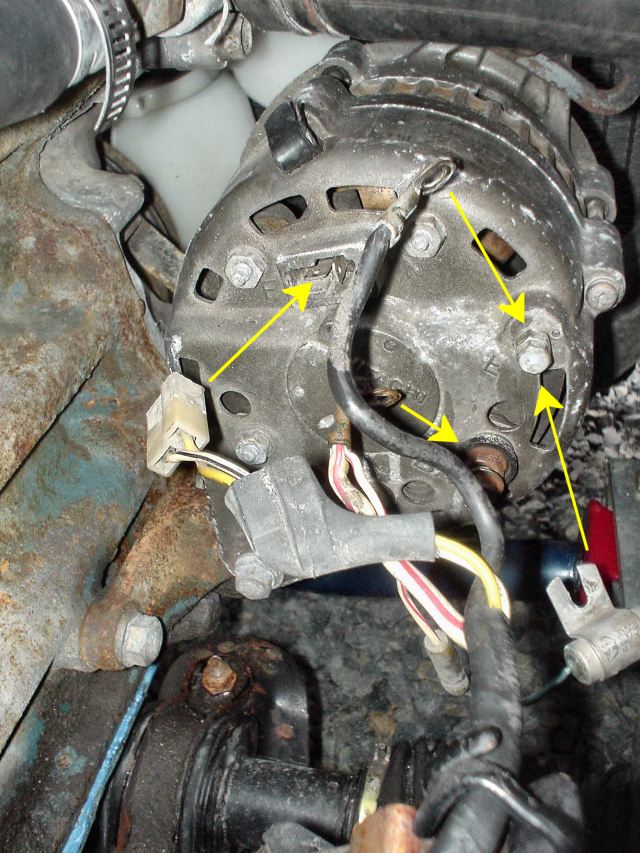

Note that all three needed connectors are the same:

- E (Black Wire and Condenser) This

connection is Earth or Ground

- BAT (White wire with Red Stripe and other end of condenser

wire) This connection is +12V output

- F&N (T connector)

N (Yellow) (on the early alt becomes the Sense signal on the newer alternator (the

alternator "senses" the voltage on this wire and attempts to

maintain it at 14.45V.

F (white with black stripe) is the Field signal on the early alt that becomes the L lamp signal

on the newer alternator.

From the top. The ZX on the left is clearly bigger. It is rated at 60A

compared to the Z's 50A

Pulleys seemed to be the same but ZX fan on left is bigger

Ths Swap:

Disconnect - Neg battery terminal (note I repositioned my battery so that the

- neg side is near the firewall).

Here is a pic of the stock 77 alternator before doing anything (use as a

reference if needed)

Here is a another reference pic

FYI Name plate on stock 77 alternator "12V @ 50A"

Disconnect the cables to the alternator

Remove 3 bolts that hold alternator in place. I used a 13mm socket for the top

bolt that clamps it to the bracket and a 12mm socket for the two bolts holding

it to the engine block.

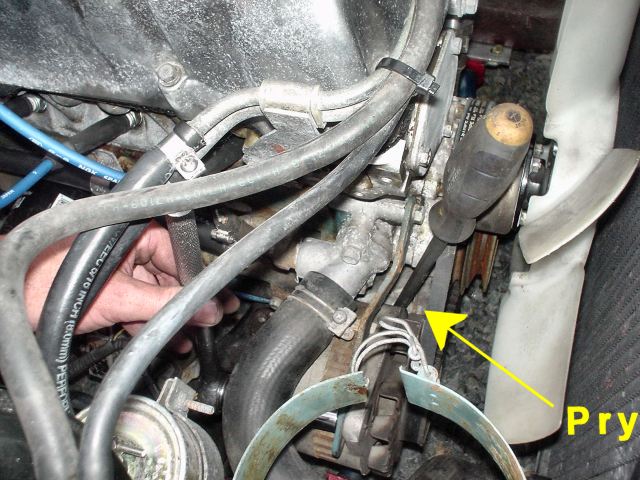

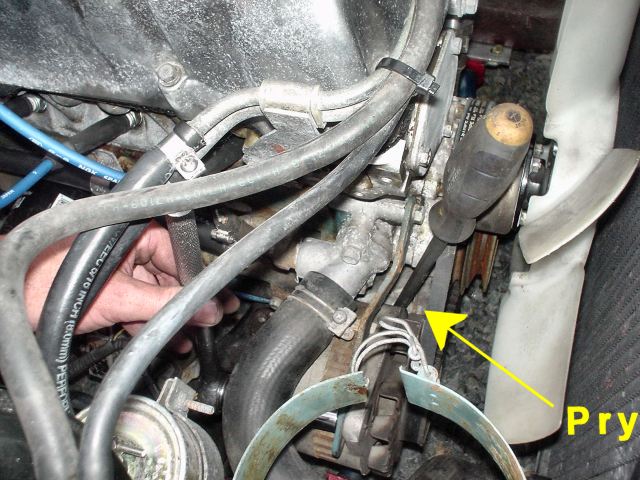

Here is a pic of an easy way to access the lower front bolt. The rest of the

work can be done from the top.

Unclamping the carbon canister and moving it aside takes 30sec to do and helps

a lot.

Alternator removed

Freshen contacts/connectors on new alternator with sandpaper or scotch pad and

contact cleaner (Caig Deoxit above)

You just need to do the BAT, E and "T" contacts. Also do the same

with the cable ends in the car.

Install new alternator:

- Bolt it in place with 3 bolts but only turn

them to "finger tight"

- Install the fan belt

- Use a long screwdriver or broom handle or

similar to pry the alternator away from the engine as shown above. Tighten

the top bolt with a ratchet while the fan belt is in tension.

- Check tension by pressing firmly on fan

belt. ~ 1/2" deflection is fine.

- Tighten all 3 bolts

- Re-connect wires

Locate Voltage Regulator. It is under the bracket holding the fusible links. A

10mm socket removed the 4 bolts.

Here is the bracket removed. You can see the Voltage Regulator and it's inline

connector

Here is a schematic of the ZX alternator. Note the

internal voltage regulator.

- BAT (+12V battery) connection (White with

red striped)

- E (earth/ground) connection (Black) are the

same on both alternators and require no changes.

- S (Sense) connection (Yellow) gets connected

to a +12V source

- L (Lamp) connection (White with black

stripe) gets connected to a +12source that is active only when the car is

cranked by the starter. (You can see the node in the schematic where the L

lines get power from the warning lamp when cranking and then from the

alternator windings via the 3 clustered diodes when operating)

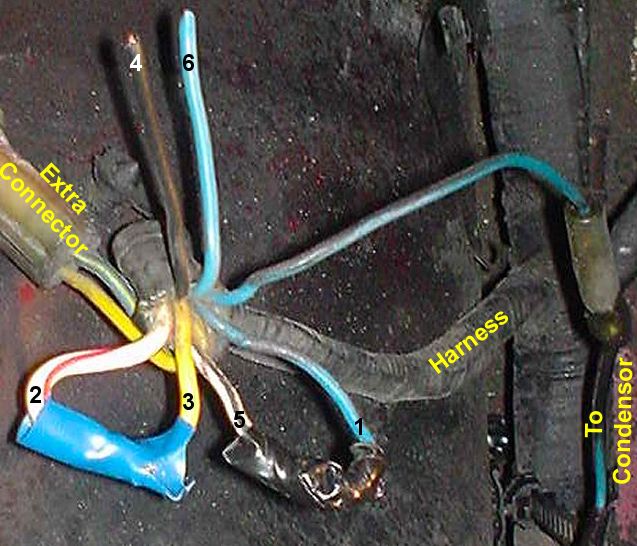

Electrical Jumpers

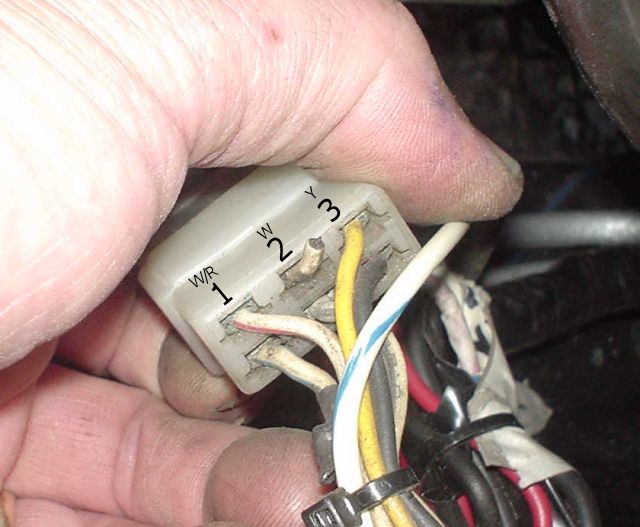

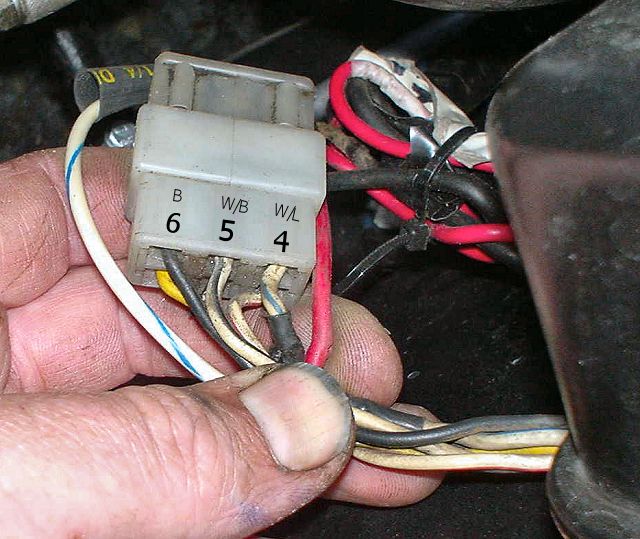

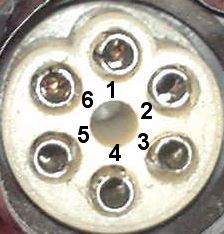

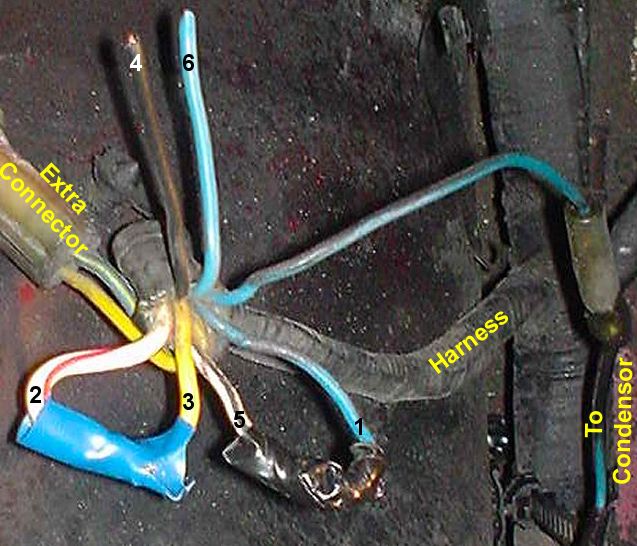

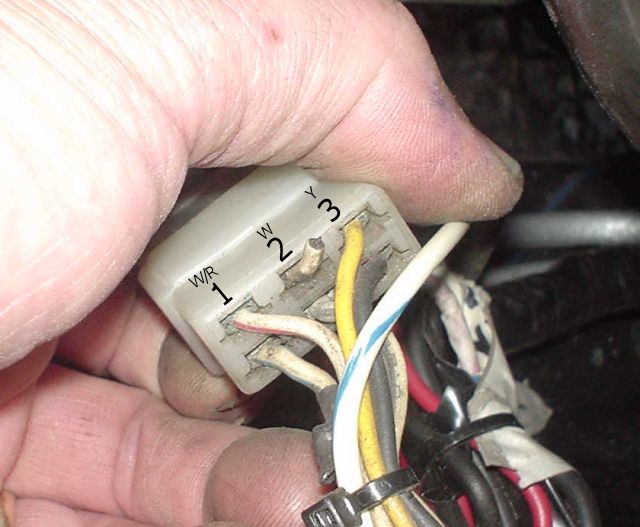

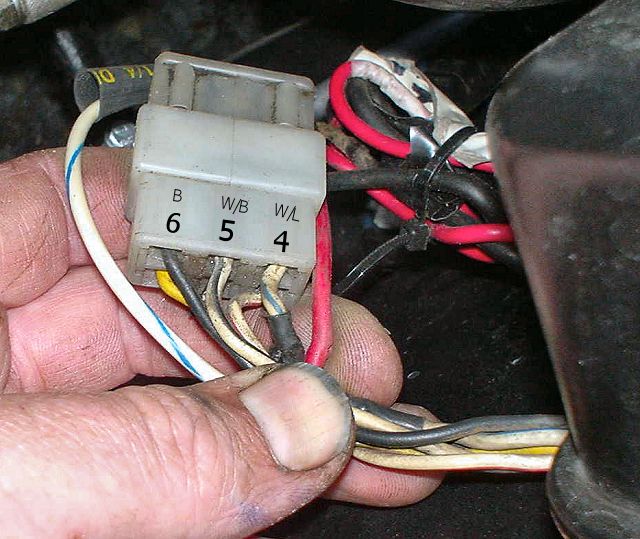

This is the wiring to the electrical harness connector (as seen on the car

when you unplug, remove, smash into bits, tramp on and throw away the

external voltage regulator)

Here are the two connections to make: 2 to 3 and 1

to 5.

Connect, solder, heat shrink, insulate and wrap

Double check everything (wires correct and

snug, bolts tight, fan belt snug and on correct pulleys, no tools in engine

compartment, carbon canister put back and hose put on, correct jumpers at

connector)

Connect -neg battery cable briefly (1sec) and make sure there are no sparks or

smoke!

If all seems ok, connect -neg battery cable and try starting. Watch for smoke

and watch the battery gauge for correct voltage and Red LED functioning.

Enjoy!

FYI if you have a '76 280z, the colours are

slightly different:

- The white with red striped wire on the

77 is just white on the 76 (still pin 2)

- The blue wire on the 77 is green on the 76

(still pin 6 and unused)

Here are the '76 connections for your convenience

Ok, many people are still confused. Here are

the jumper connection details for each year

| |

|

|

|

| |

1975 |

1976 |

1977 |

Connect 1-5

(lamp to windings common) |

green&red to

white&black |

blue to

white&black |

blue to

white&black |

Connect 2-3

(+12V to Sense) |

white to yellow |

white to yellow |

white&red to

yellow |

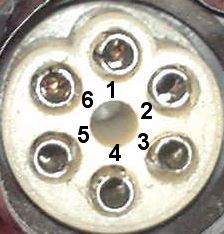

'73 240z Connector to VReg (Rectangular)

Great post on www.Zcar.com

Author: xtinc

Date: May 14, 10:48am

I followed these instructions I found on the net and it worked perfect. Also

before you do this, do a search on this site for diode. Sometimes when you

convert to an internal regulator, the car will not shutoff when you turn the

key to off, this is due to current bleeding through the alternator, a diode

must be placed in the circuit to block it

Good luck

Converting to an internal regulator alternator

Question:

I

would like to know if anyone has converted from the external regulated

alternator to an internal. What wiring did you change?

Answer:

First a

little background: The 60 amp internal regulator alternator was used on the

'78 280Z and then the non-turbo 280ZX. I have also seen it on the '78-'85 810/Maxima

and the '81-'85 720 pickup trucks. It is marked "LR160" on the case.

There was also a 70 amp version (marked LR170) that was used on the 280ZX

turbo's.

[Note: It looks like the '84-'86 non-turbo 300ZX 70 amp alternator could be

used as well, but the wiring connectors are different, so get (i.e., cut it

off) the corresponding engine harness connectors as well if you get one of

these alternators. I'll write this up this conversion later.]

Because I don't like to give instructions without some explanation of what you

are doing (it makes troubleshooting easier), I will start by describing the

internally regulated alternator's electrical connections:

1. An

"L" connection which goes to a "switched" 12V supply. By

this I mean a 12V source that is active only when the ignition switch is in

the ON position. I use the mnemonic "L" for "lamp", the

alternator warning lamp (if used) is in series with this connection. This

terminal also supplies the "excitation" current to the alternator

field winding at engine turn on, allowing the alternator to begin producing

voltage as the engine is ramping up to idle speed. Once the alternator rotor

is turning fast enough, it generates it's own supply for the field winding and

the current in the "L" connection stops flowing. The warning lamp

(if used) goes out.

2. An

"S" connection which goes as close to the positive terminal of the

battery as physically possible. The "S" connection

"senses" the battery voltage and this is the voltage that the

regulator is tying to control. This connection has a high impedance, so it

only draws only micro amps from the battery, so it can be left connected

without fear of battery discharging.

The "L" and "S" connections are in the plug connector on

the rear

of the alternator that looks like the capital letter "T". The top

of the "T" is the "S", and the other part of the

"T" is the "L". Or

in crude ASCII art:

............

: ------- : "S"

:.... | ....:

: | :

: | : "L"

:...:

3. An

"A" terminal, which is the output of the alternator, which also is

connected to the positive terminal of the battery. This connector carries the

charging current. Because of the high currents this wire must carry, it is a

low gauge wire, which means it has a large cross sectional area. For safety

reasons, a fusible link should be in series with this connector. The

"A" terminal is the insulated threaded stud on the rear of the

alternator.

Of course, someone may ask: "Why do you need two separate (the

"S" and the "A") connections between the battery and

alternator?". It is because of the fact that even large wires have some

resistance, and therefore there will be a voltage drop between the alternator

and the battery when the battery is being charged. If the regulator sensed the

alternator output (which is higher in voltage) and not the battery terminal,

the result would be undercharging of the battery. Now there are alternators

which work this way, but they need a fairly large diameter charging wire to

reduce the voltage drop. The separate "S" connection is a much

better method of regulation.

4. There

is a "P" terminal on the 280ZX turbo alternator (but I have also

seen it on a few of the non-turbo 280ZX alternators). There is not a

corresponding connector on the engine harness to mate with the "P"

terminal, even on the turbo 280ZX's. So, the "P" terminal is not

used/needed.

5.

Finally, there is a ground connection on the alternator, although the case is

a pretty good ground connection to the engine block.

Now, the following procedure only applies to the 240Z. The 260Z has electrical

connections between the regulator and the interlock module and the electric

fuel pump, so it's more difficult to convert to an internally regulated

alternator, but I have a procedure for it as well. Please email me directly if

anyone is interested. I have not looked into converting a 280Z, but I would

think that it would be possible as well.

1.

Disconnect the battery.

2. Unplug

the external regulator and note the color code of the wires that are on the

regulator connector of the engine wiring harness. You will be connecting some

of these wires together, so get another plug from a junked regulator or cut

the one off your old regulator. Now the wire colors I will be referring to are

on the regulator connector of the engine wiring harness. This is because

although the regulator wire colors match the engine harness with the stock

regulator, I've noticed that some aftermarket regulators have a different wire

color code.

3.

Connect the white wire to the yellow wire. This connects the battery to the

"S" input.

4.

Connect the black with a white stripe wire to the white with black stripe

wire. This connects the "L" terminal to a switched 12V.

5.

Disconnect and unbolt your old alternator. Bolt up the new alternator.

Depending on what particular internally regulated alternator you use (I've

seen different pulley sizes), you might need a different length belt.

6. At the

alternator, connect the white with red stripe wire of the engine wiring

harness to the threaded stud (the "A" terminal) on the alternator.

This connection provides the charging current for the battery. Connect the

black ground wire to the alternator. Don't forget to include any bypass, or

filter capacitor. Plug the two-pin "T" connector into the

alternator.

7.

Re-connect the battery and start the engine. With a good digital voltmeter

measure the voltage directly across the battery terminals. This is the

charging voltage. It should be 14.7V +/- 0.3V, but this voltage is a function

of the ambient temperature and the state of charge of the battery. If the

voltage reading is not correct, then re-check your wiring. More than 15.0V

indicates that the "S" connection may not be connected correctly.

Author: Pellius

Date: Jul 5, 7:08pm

BTW, with regard to the terminal

marks on the GM alternator case:

GM/Delco "1" = GM/Delco "R" = Datsun "L" = warning lamp/Switched +12v

GM/Delco "2" = GM/Delco "F" = Datsun "S" = constant +12v current sensor